Project Leader: Daniel Kiener

In recent years, integrated circuits (IC) have become ever smaller and more complex (e.g. stacked circuit paths). Since such microelectronic devices should exhibit a reliable performance under different loading and environmental conditions, it is extremely important to investigate the failure behaviour of their components in simplified systems (e.g. tungsten film on silicon). A main interest lies on the determination of the fracture behaviour. However, since the residual stress distribution strongly influence the fracture toughness values, it has to be investigated first.

Possible reasons for residual stresses in the thin films are:

- film deposition

- applied loading conditions

- different material properties between various films (thermal mismatch, crystallographic structure,…)

Residual stress measurements

To determine the residual stresses very locally, micro bending beams are fabricated using a combination of broad beam ion milling (see Hitachi E-3500) and focused beam ion milling (see LEO 1540XB). For measuring the local residual stress distribution the film in the rear part of the cantilever is gradually reduced, leading to a change in the deflection of the beam.

Our experimental technique called ILR (incremental layer removal) method allows to determine complex stress profiles in multilayered thin films with outstanding depth resolution, as shown here (youtube).

The segmented video shows how the thickness reduction in the rear part of the cantilever (top left) influences the deflection of the beam (top right). The interface positions are determind from an inclined view (bottom left). Analysis of the data provides the residual stress distribution (bottom right).

More details on the experimental determination of residual streses in multilayers can be found here.

An improved analytical and numerical treatment of the stress analysis is provided in this recent open access article.

Fracture Toughness Measurements

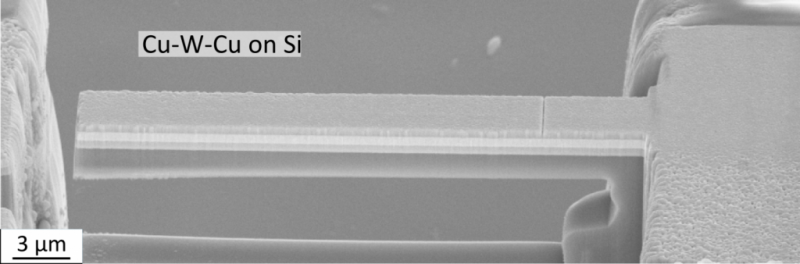

Micro bending beams for fracture toughness investigations are prepared in analogy to the cantilevers for residual stress measurements. The only difference is that the beams for fracture experiments are only a third of the size compared to those for stress measurements. All loading experiments are carried out in an in-situ scanning electron microscope (see LEO-982).

This video (youtube) shows the fracture experiment of an 1500 nm thick W-Cu-W film on Si.

Material: Besides single layers such as W on Si and Cu on Si, also multilayer systems with hard-soft interfaces are be investigated (e.g. CuWCu on Si) to study crack arrestor situations. Generally, this method is applicable to a vast variety of thin film systems.

A detailed experimental and numerical evaluation of the crack driving forces and fracture properties in such multilayer systems, taking into account variations in elastic/plastic properties as well as residual stresses, can be found here.

Determination of interface strength

There are several small scale techniques to determine the strength of interfaces, as shown in the graphic below. However, typically they always determine the weakest interface. Thus, we derived a novel miniaturized shear experiment capable to determine the interface strength or energy release rate of strong interfaces in the presence of weak ones, see d. Details are reported here.