Nanocrystalline and ultrafine grained materials have been a subject of extensive research over the past couple of decades due to their unique mechanical and functional properties. Although several routes to obtain such materials are currently known, one of the most efficient processes is severe plastic deformation. High pressure torsion (HPT) processing, for example, is a very effective way to generate ultrafine grained or even nanocrystalline microstructures from initial coarse grained single phase materials. Unfortunately, the processed structures are thermally unstable due to the high amount of stored energy in their large grain boundary area, and coarsening of the microstructures (even at room temperature) alters material properties considerably. As a consequence, the thermal stability of nanocrystalline and ultrafine grained materials is a fundamental issue for future potential applications.

The aim of this project is the development of novel HPT-processed composite materials, in which the major issue of structural instability is overcome. Carbon nanotubes (CNTs) dispersed throughout a Ni matrix can stabilize the microstructure against grain growth. Additionally, due to their outstanding intrinsic properties, CNTs are expected to improve the mechanical and tribological properties as well. To achieve this goal, the HPT process will be optimized to obtain a homogeneous dispersion of the CNTs within the matrix, and the effect of the highly energetic HPT processing on the CNTs will be thoroughly studied. Additionally, an advanced characterization of the microstructural state through the different processing steps (as-sintered, as-deformed and annealed) will be performed. The comprehensive microstructural characterization in combination with an examination of the CNT influence on the mechanical and tribological properties as well as on thermal stability of SPD processed CNT-reinforced metal matrix composites will be used to find the governing structure/property relationships which can describe the optimal material performance. Such structure/property relationships will provide a tool for the optimization of CNT-based composites with well-defined properties. Therefore, the proposed project can serve as a starting point regarding further research in this area with other matrix materials and other types of reinforcement phases. Additionally, these results will be useful for the evaluation of these composites from a scientific perspective as suitable candidates for mechanical applications.

The aim of this project is the development of novel HPT-processed composite materials, in which the major issue of structural instability is overcome. Carbon nanotubes (CNTs) dispersed throughout a Ni matrix can stabilize the microstructure against grain growth. Additionally, due to their outstanding intrinsic properties, CNTs are expected to improve the mechanical and tribological properties as well. To achieve this goal, the HPT process will be optimized to obtain a homogeneous dispersion of the CNTs within the matrix, and the effect of the highly energetic HPT processing on the CNTs will be thoroughly studied.

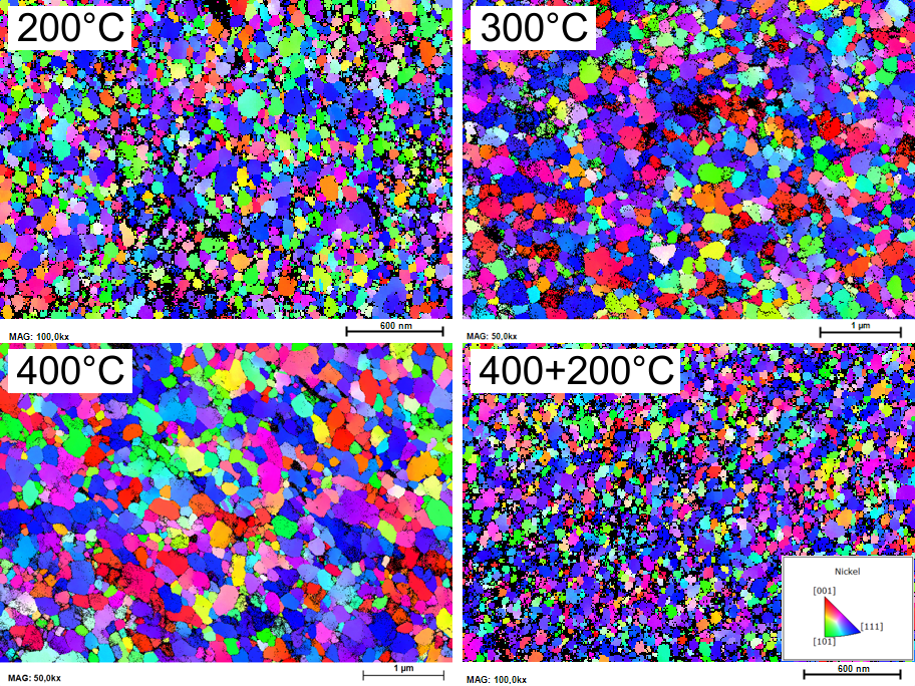

Additionally, an advanced characterization of the microstructural state through the different processing steps (as-sintered, as-deformed and annealed) will be performed. The comprehensive microstructural characterization in combination with an examination of the CNT influence on the mechanical and tribological properties as well as on thermal stability of SPD processed CNT-reinforced metal matrix composites will be used to find the governing structure/property relationships which can describe the optimal material performance. Such structure/property relationships will provide a tool for the optimization of CNT-based composites with well-defined properties. Therefore, the proposed project can serve as a starting point regarding further research in this area with other matrix materials and other types of reinforcement phases. Additionally, these results will be useful for the evaluation of these composites from a scientific perspective as suitable candidates for mechanical applications.

Scientific Publications

Aristizabal, K., Katzensteiner, A., Bachmaier, A., Mücklich, F., Suárez, S., Microstructural evolution during heating of CNT/Metal Matrix Composites processed by Severe Plastic Deformation, 2020, Scientific Reports 10(1), 857, DOI: 10.1038/s41598-020-57946-3, pdf

Katzensteiner, A., Rosalie, J.M., Pippan, R., Bachmaier, A., Synthesis of nanodiamond reinforced silver matrix nanocomposites: Microstructure and mechanical properties, 2020, Materials Science and Engineering A 782,139254, DOI: 10.1016/j.msea.2020.139254, pdf

Bachmaier, A., Katzensteiner, A., Wurster, S., Aristizabal, K., Suarez, S., Pippan, R., Thermal stabilization of metal matrix nanocomposites by nanocarbon reinforcements, 2020, Scripta Materialia 186, pp. 202-207, DOI: 10.1016/j.scriptamat.2020.05.014, pdf

Aristizabal, K., Tayrac, A., Katzensteiner, A., Bachmaier, A., Suárez, S., Friction and tribo-chemical behavior of SPD-processed CNT-reinforced composites, Lubricants 7(9), 2019, 75, DOI:10.3390/lubricants7090075, pdf

Aristizabal, K., Katzensteiner, A., Leoni, M., Mücklich, F., Suárez, S., Evolution of lattice defects and crystallite domain size in carbon nanotube metal matrix composites processed by severe plastic deformation, Material Characterization 154, 2019, 344-352, DOI:10.1016/j.matchar.2019.06.019, pdf

Katzensteiner A., Müller T., Kormout K., Aristizabal K., Suarez S., Pippan R., Bachmaier A., Influence of Processing Parameters on the Mechanical Properties of HPT‐Deformed Nickel/Carbon Nanotube Composites, 2019, Advanced Engineering Materials, 1800422, DOI: 10.1002/adem.201800422, pdf

Aristizabal, K., Katzensteiner, A., Bachmaier, A., Mücklich, F., Suárez, S., On the reinforcement homogenization in CNT/metal matrix composites during severe plastic deformation, 2018, Materials Characterization, 136, pp. 375-381. DOI: 10.1016/j.matchar.2018.01.007, pdf

Aristizabal, K., Katzensteiner, A., Bachmaier, A., Mücklich, F., Suarez, S., Study of the structural defects on carbon nanotubes in metal matrix composites processed by severe plastic deformation, 2017, Carbon, 125, pp. 156-161. DOI: 10.1016/j.carbon.2017.09.075, pdf

Aristizabal, K., Suárez, S., Katzensteiner, A., Bachmaier, A., Mücklich, F., Evolution of the microstructure in carbon nanotube reinforced Nickel matrix composites processed by high-pressure torsion, 2017, IOP Conference Series: Materials Science and Engineering, 258 (1), art. no. 012008, DOI: 10.1088/1757-899X/258/1/012008, pdf

Katzensteiner, A., Aristizabal, K., Suarez, S., Pippan, R., Bachmaier, A., Temperature dependent structural evolution in nickel/carbon nanotube composites processed by high-pressure torsion, 2017, IOP Conference Series: Materials Science and Engineering, 194 (1), art. no. 012019, DOI: 10.1088/1757-899X/194/1/012019, pdf