We encounter miniaturized objects in our daily life, as they are present, for example, in integrated circuits, cell phones, flexible displays, or various miniaturized sensors or actuators, in the form of thin films, conducting wires, or more complicated structures. And we are used to the fact that these objects get ever smaller and cheaper.

However, once material dimensions are reduced to the micron- and sub-micron range, material properties are subject to significant change. Thus, mechanical properties start to depend on the sample size. Moreover, due to the large surface-to-volume ratio of small structures, deformation mechanisms are subject to change.

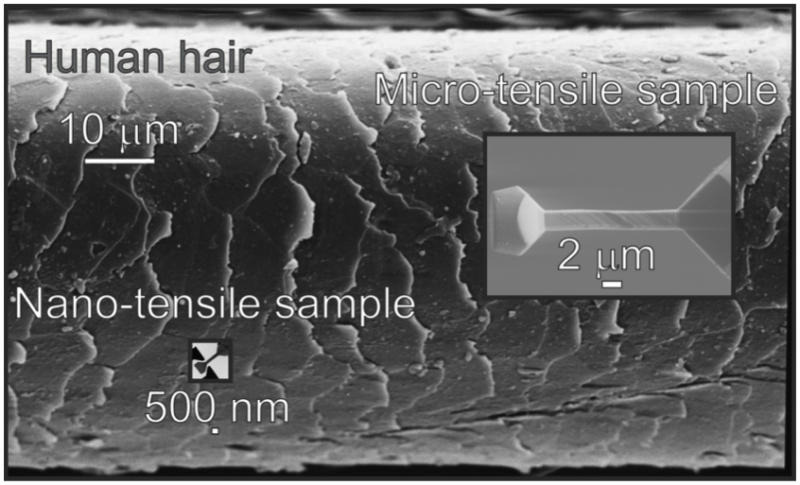

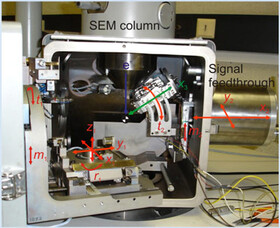

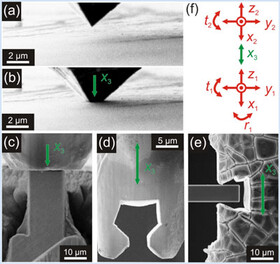

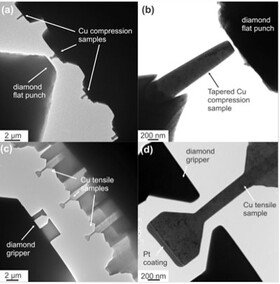

To unveil the basic mechanisms governing deformation in small dimensions, we use advanced techniques to structure such small samples and perform quantitative miniaturized experiments directly inside electron microscopes like the SEM or TEM . The direct observation of the sample deformation in combination with the mechanical data allows for a comprehensive understanding of the governing processes.