Project Leader: Megan Cordill

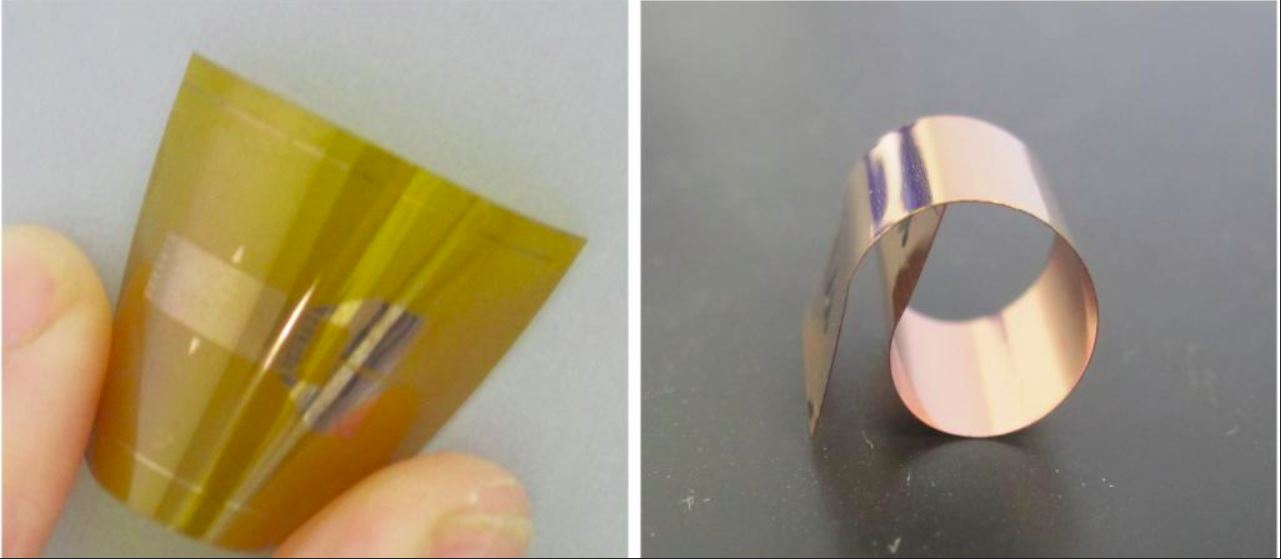

Deformation and interfacial adhesion of thin films on polymer substrates govern the performance and reliability of many designed systems such as flexible microelectronic devices, electrotextiles, and flexible displays. Promising concepts use state-of-the-art technologies such as organic light emitting diodes, thin film transistors, and flexible liquid crystal displays. Of top most importance in designing reliable flexible devices is to understand interface properties between these materials. Advances must be made in the relationship between film adhesion, mechanical properties and fracture which are currently poorly understood for metal films on compliant polymer substrates in order to provide the basic understanding required for design guidelines.

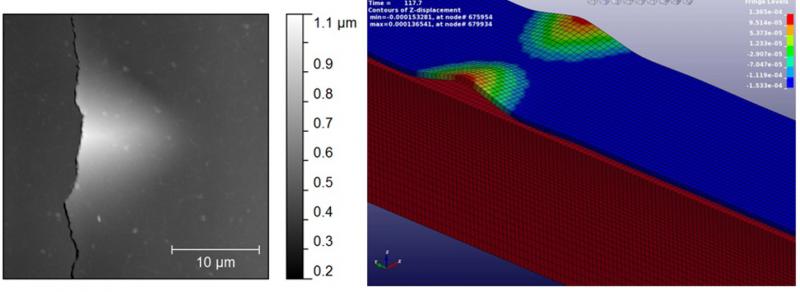

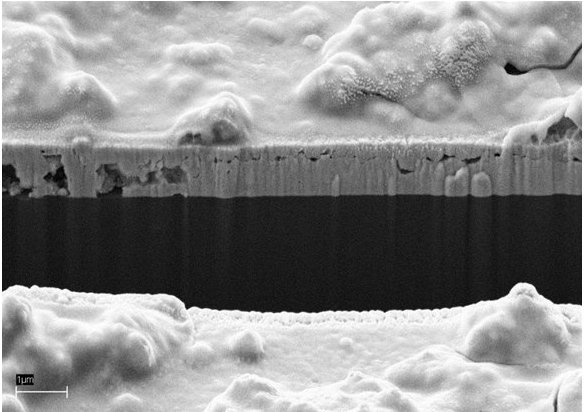

During the course of this project, an adhesion measurement technique for metal films on polymer substrates based on fragmentation testing as developed. The technique can be used on brittle films, thin ductile films, and ductile films with a hard overlayer. The delamination process has also been modeled with finite elements. The effect of straining temperature and chemistry on adhesion was also studied with advanced TEM.

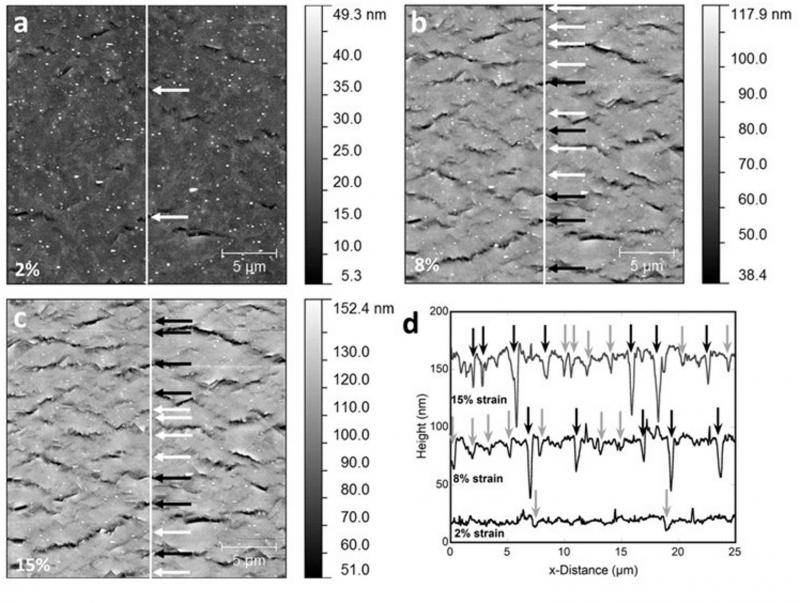

Also within the project in-situ AFM straining for ductile films was developed making it possible for the first time to quantify the amount of deformation and cracking of ductile films. The technique has been used to study the effect of film thickness and grain size on film deformation and cracking as well as adhesion of thin ductile films with a brittle adhesion layer.

In-situ stress measurements during tensile straining, in two directions, to determine yield stresses and buckling stresses were also performed. The role of film thickness, grain size and the use of an interlayer were investigated with these experiments. Results indicated that a critical stress may be necessary to induce delamination and elucidated the role of brittle adhesion layers on the mechanical failure of the film.

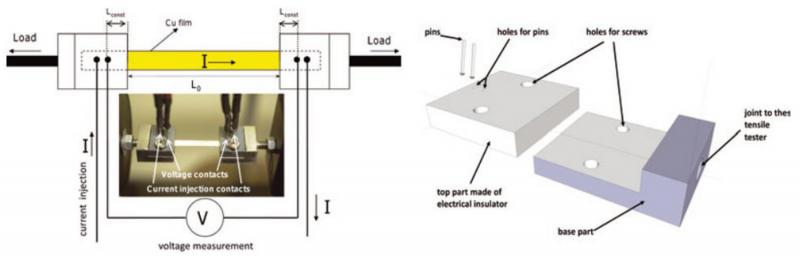

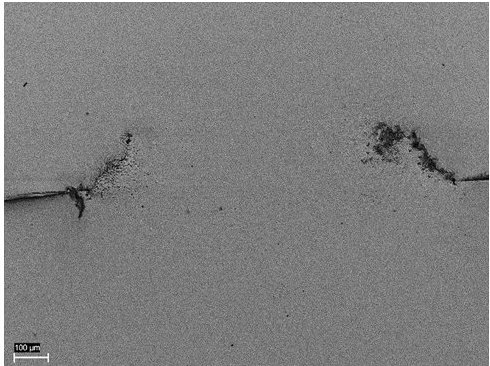

In-situ 4PP measurements on three different straining stages were developed. These experiments allowed for the electro-mechanical behavior of metal films on polymer substrates to be examined. Notable results are that the resistance recovers after unloading and continues to recover after removal from loading frame, under cyclic loading the resistance can improve due to grain growth, and the development of an in-situ-squared experiment where the electrical resistance and deformation/cracking are combined into the same experiment.

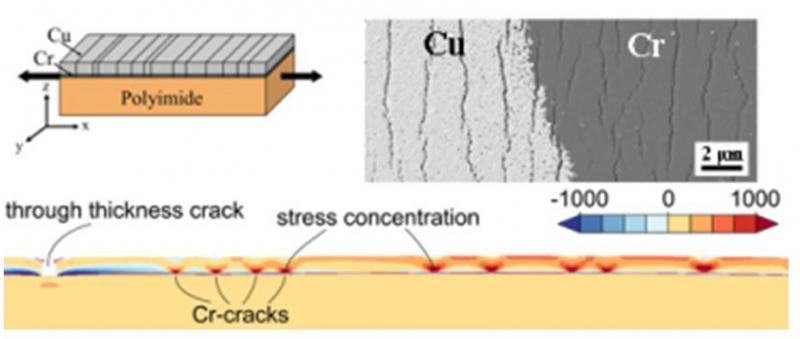

Other interesting results imply that the use of brittle interlayers may not be necessary. Through experiments (in-situ AFM, XRD, 4PP) and simulations, it was observed that when cracks formed in the brittle adhesion layer, these cracks act as stress concentration sites for the overlying film. The adhesion layer also dominates the mechanical behavior of the film in a negative way; especially when it is thin (100 nm or less). Cu and Au films with and without a 10nm Cr interlayer were examined and similar results were found. Films cracked more with an interlayer thus reducing the electro-mechanical functionality. The interface structure responsible for the improved electro-mechanical behavior without an interlayer is still under investigation.

Hygrothermal effects from the substrate were studied. The more depth studies were performed with Cu and Cr on PET. Film-substrate samples were immersed in water and saline solutions and subjected to different humidities for different times. It was found that the Cr film and PET substrate were virtually unaffected by the liquid environments providing the same elastic modulus to as-received materials when strained. However, the Cu film corroded even after 1 hour of exposure to water. Another study on the strain rate sensitivity and polymer structure found that for the Cr-PET system, the main influencing factors are the Cr film thickness and temperature which can affect the crack spacing and adhesion. It can be concluded that flexible electronic devices should have a protective coating to prevent corrosion and oxidation of the conductible layers and that PET is a robust substrate to use for flexible electronic applications as long as the temperature remains low.

A final study on the use of electromigration to heal cracking in flexible electronic devices was also performed. Using a Au film with a Cr interlayer to create defined areas of damage, high current densities were applied to the film (1 MA/cm3) to induce electromigration. The current densities used were much higher than typically applied to flexible electronics (1 µA7cm3). By carefully controlling the temperature of the whole system (Au and PI substrate) with a heat-sink and slowly increasing the current density, experiments could be performed for up to 7 days. It was found that electromigration does occur near the probes where the current was applied, but not necessarily enough to self-heal cracks. Further experiments are underway to better understand the possible mechanisms that are occurring.