Thin film buckle-delamination - Dundurs parameters influence

Project Leader:Dr. Stanislav Zak

Abstract

In recent years, there has been a strong push towards the modern flexible electronic devices, such as foldable phones or wearable biosensors and electronics. These devices are composed of numerous thin layers of metallic and non-metallic materials and they must withstand harsh usage and a large number of bends and deformations. For example, a foldable smartphone should be able to undergo more than 100 000 open-close cycles without any electrical and mechanical failure. Such strict conditions of use bring high demands not only on the used materials, but also on the connection between them. Therefore, an attention to the adhesion between dissimilar materials has to be investigated.

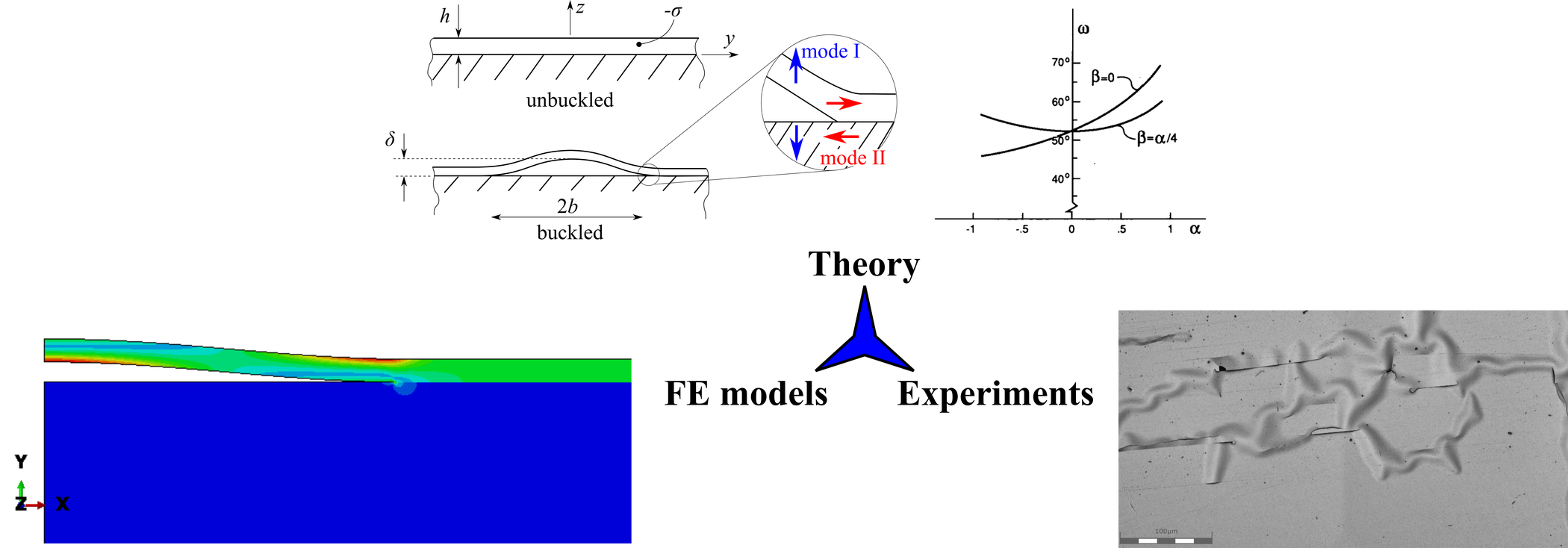

One way to quantify the adhesion between thin film and substrate material is the buckling-induced delamination which uses compressive stress in the thin layer to form a buckle and delaminate it from the substrate. However, the nature of the method itself induces normal and shear loading combination at the tip of the delamination crack and it is important to be able to separate these two components. For this reason, a mode-mixity parameter describing the ratio between shear and normal loading has been introduced 30 years ago. However, in such time, there was only a limited number of material combinations used in real applications, therefore it was deemed that the influence of mismatch between material properties of the film and substrate can be taken as constant, regardless of the material parameters mismatch. Contrary to this, recent advances in the field of modern materials science promote the use of strongly dissimilar materials combinations, such as metallic thin films on polymer or ceramic substrates. The introduction of such materials raises a question if the 30 years old simplification can be still used. Recent research shows that it cannot and the material mismatch has to be accounted for.

This project will combine the numerical modelling, analytical approaches and experimental measurements of the thin films adhesion in order to quantify the ratio between normal and shear loading for strongly dissimilar materials as a function of the so-called Dundurs parameters. The numerical modelling enables us to check the materials mismatch influence for endless material combinations and experimental techniques will be used to obtain input data as well as validate the models and the research hypotheses, leading to a better understanding of the material delamination processes and, therefore, more durable modern devices.

Results presentations

1) GRC Structural Nanomaterials: Design, Microstructure and Mechanical Behavior of Structural Nanomaterials conference (Les Diablerets, Switzerland, May 8 - 13, 2022) - poster presentation

2) ICMCTF 48th International Conference on Metallurgical Coatings and Thin Films (San Diego, USA, May 22 - 27, 2022) - oral presentation

3) MSMF10 Materials Structure and Micromechanics of Fracture conference (Brno, Czech Republic, September 12 - 14, 2022) - oral presentation

Acknowledgement

FWF

Project type

FWF ESPRIT

Projekt number

ESP 41-N

Mentor

Co-Proposers

Dr. Alice Lassnig

Dr. Miroslav Hrstka (Brno University)

Duration

01.02.2022 - 31.01.2025