IMPROVEMENT OF CRACKING RESISTANCE OF METALLIC LAYERS BY INTERFACIAL ENGINEERING OF DUCTILE LAYERS FOR FLEXIBLE OSR

Project Leader: Megan Cordill

ESI Team Members: Alice Lassnig, David Gebhart

ESA Team Members: Gabor Milasan

ESI TOPIC: Complex Materials

Summary

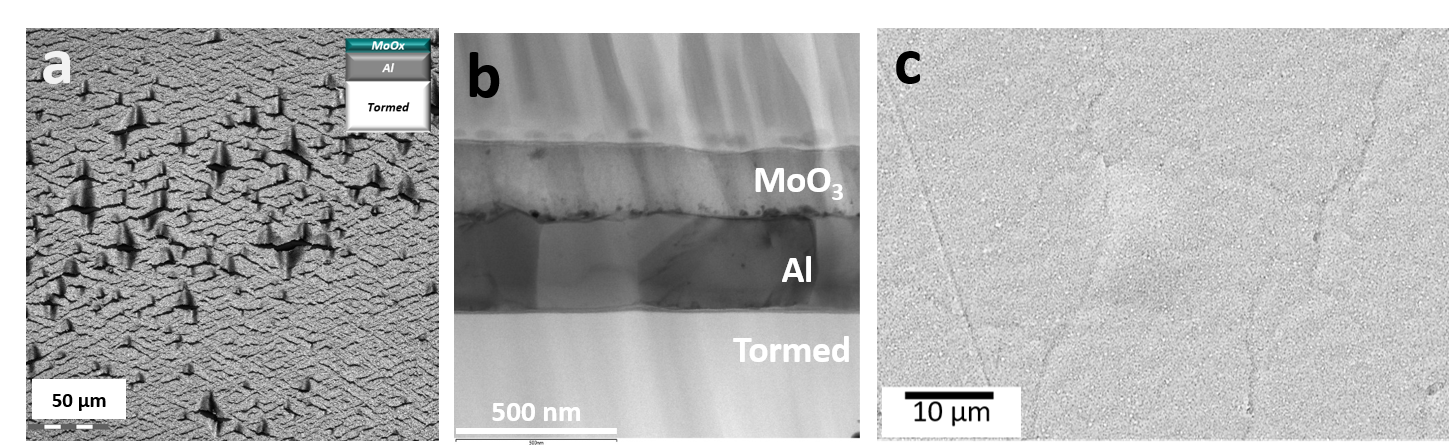

Satellites and their components are complex machines that must be able to withstand the harsh environment of space, including extreme temperature cycling, atomic oxygen, radiation, and debris. Therefore, material selection is critical for mission success. In order to help reduce the weight of optical solar reflectors (OSRs), flexible OSRs are envisioned by replacing the glass substrate with lightweight transparent polymer substrates. The change from rigid glass to flexible polymer substrates will also allow ORS to be foldable, reducing weight. Current OSR materials systems utilize Inconel, silver (Ag), and Teflon (FEP), but it has been demonstrated that the Ag-FEP interface is not stable and the Inconel/Ag films crack almost immediately with thermal cycling. Therefore, in order to achieve flexible OSRs, a new material system is required. A candidate material system is the MoO3/Al/Tormed (transparent polyimide) and it has been examined for thermal stability, long term adhesion quality, and bendability. MoO3 is a hard, transparent coating that is also resistant to atomic oxygen. The Al/Tormed interface is quite stable with good adhesion and less mobility (no void formation as with Ag) of the atoms. The MoO3/Al/Tormed film system has an especially good adhesion because normal testing conditions could not induce delamination after 24 hrs of annealing at 200°C in 10-6 mbar vacuum. The system shows some deformation and cracking when strained under uniaxial tensile to approximately 10%, however a special sample geometry that applies more strain was necessary. The same material system was studied with bending loading to assess its suitability for foldable applications, using testing methods developed for flexible electronics. It was found that the very thin substrates (25 µm) are ideal to inhibit any mechanical damage to the film stack. No cracking or deformation was observed after 10,000 bending cycles at the applied bending strain of 0.6% (bending radius of 2 mm, smaller then industry requirements). The new material system of MoO3/Al/Tormed is a good candidate for flexible OSRs. This material systems is part of the European Materials Aging (EMA) program (https://www.esa.int/Enabling_Support/Space_Engineering_Technology/Orbital_space_ageing_tests_offered_for_space_age_materials) at ESA. After simulated LEO and real LEO exposure, the system can be further tailored for flexible OSR use.

Figure 1: (a) MoO3/Al/Tormed (ESI3) cracks and delaminates when strained in tension. The resulting buckles were used to measure the adhesion energy of the Al-Tormed interface to be about 60 Jm-2. (b) Annealed for 24 hrs ESI1 MoO3/Al/Tormed side and the respective elemental maps of O, Al, and Mo. (c) SEM images after 10,000 bending cycles of 1.25% strain. Damage spacing is over 10 µm and does not appear to be through thickness damage.

Acknowledgements

European Space Agency (ESA)

Project Number

4000129515/NL/KML/rk

Project Duration

01/2019 - 03/2022