The FemtoTools FT-NMT04 is a cutting-edge nanoindentation device that enables precise mechanical characterization of materials at the nanoscale through a wide range of testing applications. Thanks to its modular design and integration with the scanning electron microscope (SEM), in-situ nanoindentation experiments as well as micro- and nanomechanical testing using different geometries can be straightforwardly conducted. Ex-situ nanoindentation experiments can also be performed in a controlled environment. The device offers various testing modes, including continuous stiffness measurement (CSM) and dynamic mechanical analysis (DMA). It features a piezo drive to achieve positioning with nanometer precision, with a noise floor of 50 pm. As the first commercially available nanoindentation device featuring a MEMS-based force sensor fabricated entirely from a single crystalline silicon wafer, it enables high sensitivity and resolution of the force readout, featuring a force range from 200 μN to 200 mN, with a noise floor of 0.5 nN. Moreover, the small mass of the force-sensing component enables CSM measurements at high frequencies and the acquisition of rapidly occurring events. Furthermore, the rapidly actuating indenter can acquire high-resolution nanoindentation maps in short timeframes

Specifications

- Interchangeable microforce sensing probe with a variety of force ranges

- Achievable force range of 200 μN to 200 mN

- High-temperature probe with a maximum achievable temperature of 800°C

- Three-axis piezo-based nanopositioners with a 1 nm noise floor

- One-axis capacitive flexure-based piezo scanner with 0.05 nm noise floor

NANOINDENTATION

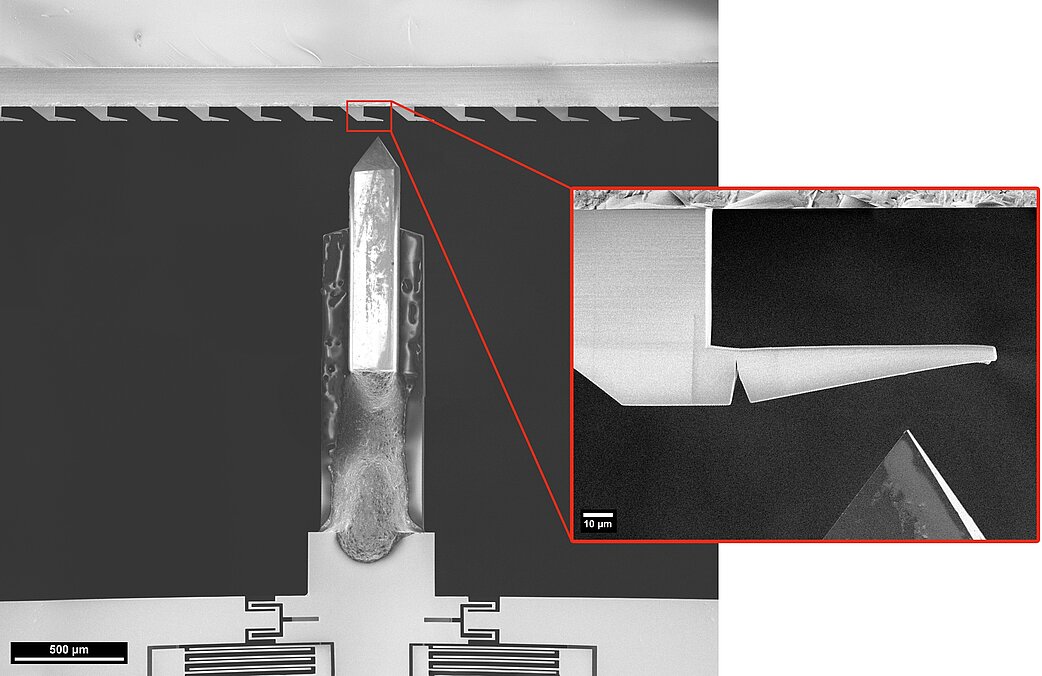

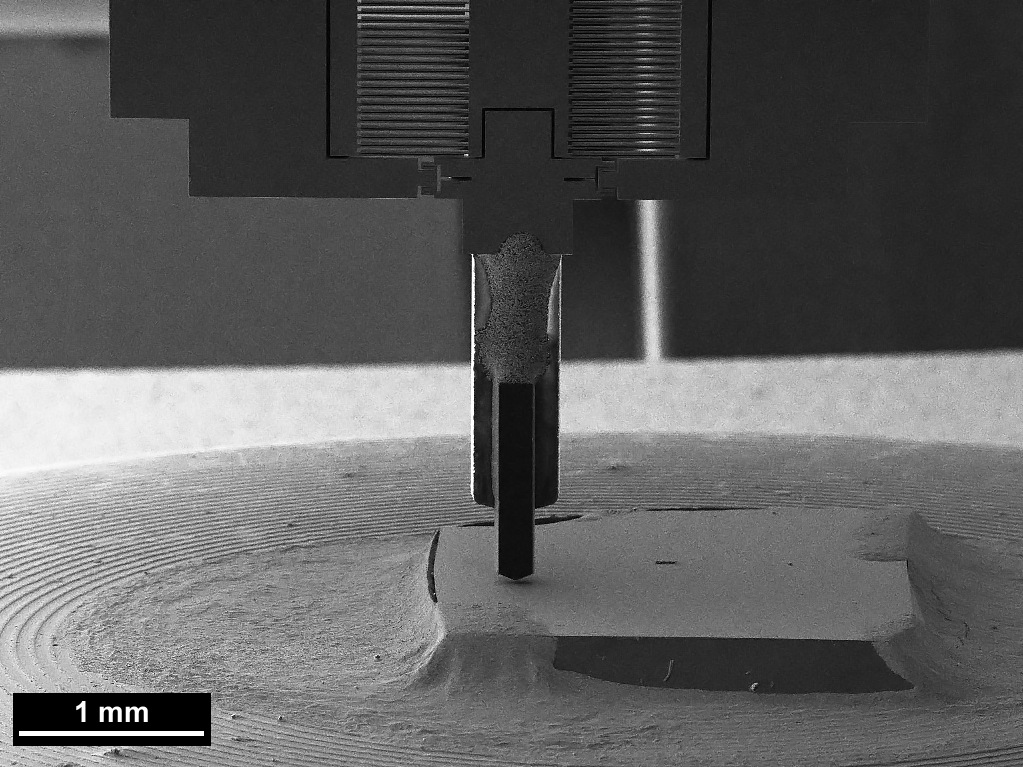

In-situ nanoindentation inside the SEM is a powerful technique for nanoscale materials characterization. By combining the imaging capabilities of the SEM with the precision of the FemtoTools FT-NMT04, the deformation behavior of materials under controlled loading conditions can be observed and recorded in real time. Thanks to its compact size, the system is well-suited for in-situ nanoindentation inside the SEM, which allows performing highly accurate and reproducible indentation tests. The method is particularly interesting when characterizing localized regions found in nanocomposites or microelectronics components. It can also provide valuable insights into the microstructural changes and deformation mechanisms during mechanical testing at elevated temperatures of up to 800°C.

MICROMECHANICAL TESTING

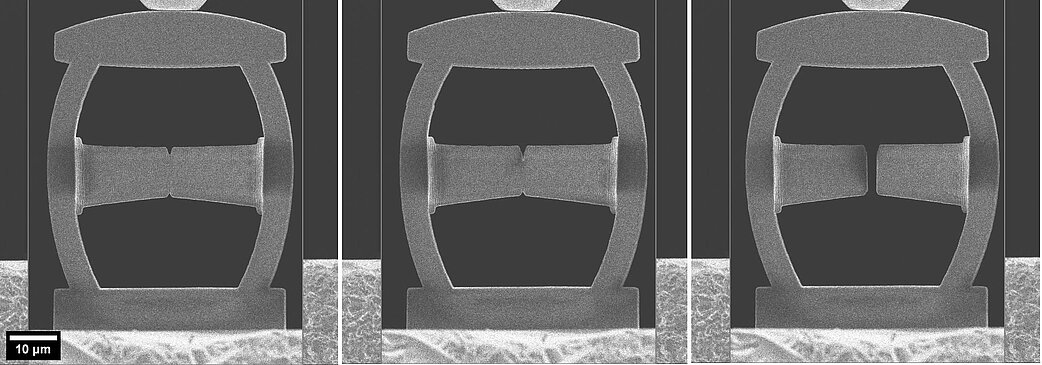

The FemtoTools FT-NMT04 is able to perform micromechanical materials testing inside the SEM on microscale samples having different geometries, such as tension, compression and bending. By analyzing the load-displacement data, important properties such as strength, ductility, strain hardening, and fracture behavior can be determined.

Resin-based push-to-pull devices loaded with a flat punch tip.