The cross section polisher is used for two different purposes:

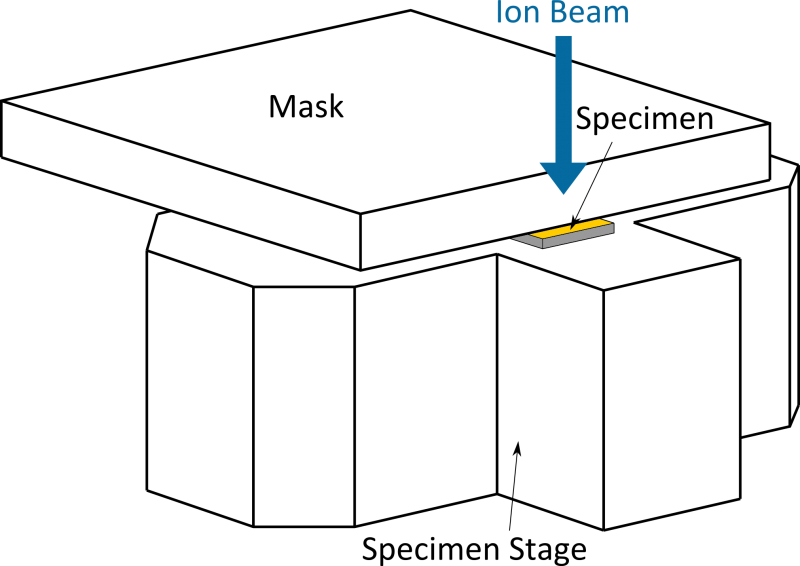

It can be used - according to its original purpose - for a smooth ion polishing of materials cross-sections that cannot be processed by other means such as mechanical or electro-chemical polishing. This gives the possibility to perform cross-sections of stacks of different materials, powder particles, porous materials, or even plastics and paper. Figure 1 shows the procedure for producing a cross-section through a fracture surface, unveiling the deformation processes happening underneath the surface. Therefore, the rough fracture surface is filled with epoxy and subsequently the argon ion beam removes material that is not protected by a sputtering mask (Figure 2).

The second, even more important purpose, is the pre-preparation of materials for subsequent FIB-production of miniaturized specimens for micro- and nano-mechanics, as documented below: