Project Leader: Andrea Bachmaier

Background

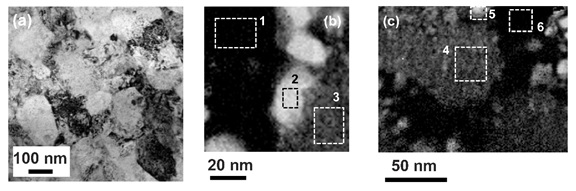

The stability of nanocrystalline metals is a fundamental issue for future potential applications. Adding solutes, impurity elements and second phase particles can stabilize a nanostructure against grain growth. The underlying mechanism for controlling the stability – reduction of grain boundary energy by solute segregation or kinetic barriers for grain boundary migration by solute drag or second phase particles- is still under discussion and is investigated in detail in the Co-Cu model system in this project. Synthesis of bulk nanocrystalline metallic materials with different types and amounts of solutes and impurity elements, is conducted by severe plastic deformation and electrodeposition. The Co-Cu system has a positive heat of mixing, and the formation of non-equilibrium solid solutions can be studied. Furthermore, it exhibits extraordinary magnetic properties like giant magnetoresistance.

The initial microstructures (e.g. texture, etc.) of the synthesized nanostructures are strongly dependent on the used processing method used. In this project, a direct comparison of the thermal stability of electrodeposited and severe plastically deformed nanomaterials and the influence of their initial microstructure regarding different defect density, different types of grain boundaries and distribution of solutes on stability, can be conducted. This helps to understand the relation of structure to stability and identify the mechanism controlling stability. Special attention is drawn to the influence of solutes and impurity elements on the mechanical properties of the nanocrystalline materials. Possible formation of supersaturated solid solutions, decomposition processes, their influence on thermal stability and the mechanism behind bulk mechanical alloying are investigated as well.

The results of the project can be used as a basis for enhancing structural stability in nanocrystalline materials and creating stable bulk nanocrystalline metallic materials in the future, which increase their potential applications.

Full –texts of all publications can be found on Researchgate

Scientific publications

Müller, T., Bachmaier, A., Konetschnik, R., Schöberl, T., Pippan, R.

Mechanical properties of electrodeposited amorphous/crystalline multilayer structures in the Fe-P system

(2018) Materials Science and Engineering A, 715, pp. 83-91. DOI: 10.1016/j.msea.2017.12.090

Bachmaier, A., Rathmayr, G.B., Schmauch, J., Schell, N., Stark, A., De Jonge, N., Pippan, R.

High strength nanocrystalline Cu-Co alloys with high tensile ductility

(2018) Journal of Materials Research. Article in Press.

DOI: 10.1557/jmr.2018.185

Kormout, K.S., Pippan, R., Bachmaier, A.

Deformation-Induced Supersaturation in Immiscible Material Systems during High-Pressure Torsion

(2017) Advanced Engineering Materials, 19 (4), art. no. 1600675,

Bachmaier, A., Krenn, H., Knoll, P., Aboulfadl, H., Pippan, R.

Tailoring the magnetic properties of nanocrystalline Cu-Co alloys prepared by high-pressure torsion and isothermal annealing

(2017) Journal of Alloys and Compounds, 725, pp. 744-749. DOI: 10.1016/j.jallcom.2017.07.200

Prizes and Awards

Prizes and Awards

- Müller T.: Förderpreis des VDI Bezirksverein Saar für eine herausragende Masterarbeit in der Fachrichtung Werkstoffwissenschaften, 15.04.2016, Sulzbach (Saar), Germany