Tungsten foils

Applications in fusion technology require materials with high thermal conductivity and acceptable ductility and strength both at room temperature and higher temperatures. Additionally, the materials must be resistant to activation by neutron bombardment.

A recent study focused on the development of the technique for investigating the fracture behavior of 100 μm thick rolled tungsten foils, with a purity of 99.97%. Electron backscatter diffraction (EBSD) scans reveal that the grains are elongated along the rolling direction of the foil, which has a very strong texture. The test specimens were produced by electrical discharge machining (EDM) and cracks were initiated by consecutively using a diamond wire saw, a razor blade and a focused ion beam (FIB) workstation. Fracture experiments were performed at temperatures from −196 °C to 800°C. The investigation of fracture appearance shows improved behavior and significantly higher values of conditional fracture toughness compared to bulk W-materials, which can be related to a higher degree of deformation during the production process. At room temperature and 200 °C, it slowly decreases when approaching the highest testing temperature of 800 °C. The most significant result of these experiments shows that a ductile to brittle transition temperature (DBTT) is around room temperature, which is an unusual result for any tungsten material. The fracture surfaces, investigated with a scanning electron microscope (SEM), show a transition from cleavage fracture at liquid nitrogen temperature through pronounced delamination within the foil plane at ambient temperatures to ductile fracture at the highest testing temperatures.

High-Temperature Superconductors

A future fusion device operates with superconducting coils which are cooled down to low temperatures and consume no energy – the coil electricity is nearly non-dissipative. Superconductors for ITER will be made of niobium-tin. In the power plant prototype DEMO, high-temperature superconductors will be used.

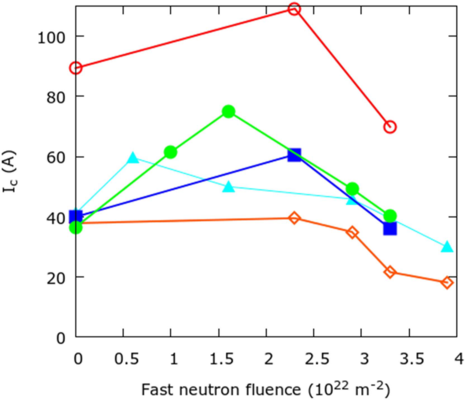

M. Eisterer et al. (Vienna University of Technology) investigate the effect of neutron irradiation on industrially constructed superconductors.